Run a Hull-PDCA cycle

No doubt that underwater hull coating is important for optimum hull performance. Now it’ s possible to make the hull performance visible for all the interested parties. CMP - Monitoring & Analysis Program (CMP-MAP) offers a valuable method of monitoring and analysis developed based on our years of experience. The method employed is original and totally unique in the marine industry in terms of analysis techniques.

Prediction & Planning

Selection of optimum high performance antifoulings based on analysis by the 'Triple CMP MAP Approach' and simulation of fuel consumption and CII ratings by the 'PIR Simulator'.

Do

Application under professional supervision

Check

Triple "CMP-MAP" approach

- 1. Operational profile analysis (report)

- 2. Power analysis (report)

- 3. FIR analysis (report)

Act

Investigation of the "CMP-MAP" reports Solution for better performance

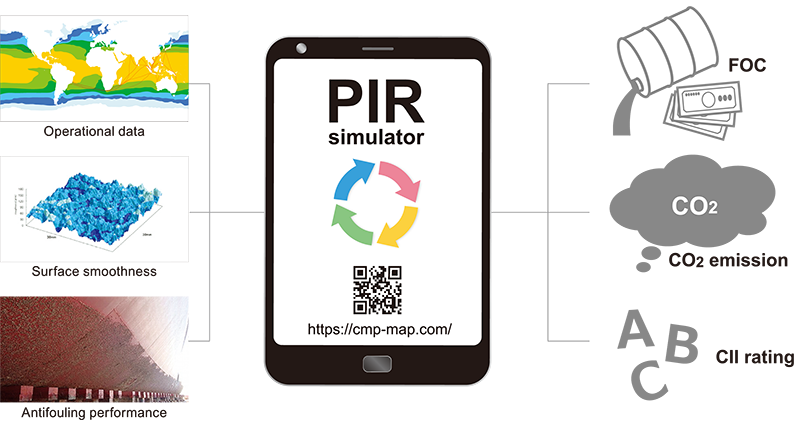

PIR simulator

PIR simulation is based on (1) vessel operational data such as activity, distance and fuel consumption, (2) coating surface smoothness parameters and (3) antifouling performance parameters to predict trends in fuel consumption and CO2 emissions as well as CII ratings.

FIR analysis

Hull Roughness vs Ship Performance

CMP has been conducting collaboration study on fluid dynamics with Tokyo University of Science, Tokyo University of Agriculture and Technology, Kobe university and National Institute of Maritime Port and Aviation Technology (MPAT), National Maritime Research Institute (NMRI).

Next-Generation Marine Environment-related Technology Development Support Project.

In the joint research theme with the Class NK and the program supported by the Ministry of Land, Infrastructure, Transport and Tourism of Japan (MLIT), CMP has developed a FIR Theory ver.3.0, 3D Hull roughness analyzer and Low friction AF.

3D Hull Roughness Analyzer

CMP developed a Portable 3D hull roughness analyzer which can measure values (Rz, Rc and RSm) on actual shipbuilding sites.

Operational profile analysis

Operational profile (Vessel’ s operating condition) is a vital factor for prediction of hull fouling and, therefore, for designing Antifouling specification. CMP developed an original operational profile analysis software and established a big database. They can visualize various cross-sectional profiles of vessel operation throughout the Antifouling service life. This enables to find or select more appropriate painting specification (type, film thickness, etc.) for each individual vessel.

Operating course

Temperature histogram

Speed histogram

Trend of activity rate

Type and film thickness of Antifouling paint (specification) is selected based on the big data analysis.

Power analysis

Biofouling has significant impact on vessel performance. CMP originally developed a hull monioring method which uses data from on-board ships. This analysis method is based on the idea of ISO19030. The indicators, i.e. speed power curve, trend curve and performance indicators are calculated for visualizing the hull performance.

Input

Data from on board ships

- Speed (Log/ OG)

- Fuel consumption / shaft power

- Wind speed and direction

- Swell height direction and spectrum

- displacement etc.

Output

Speed power curve

Trend analysis at constant speed

Hull performance Indicators

Source : The Naval Architect / January 2018 / Ship owner)

Heavy Barnacle

Slime

ISO19030

Measurement of changes in hull and propeller performance New standard on performance monitoring

CMP has been participating in the pilot maritime cluster joint research project for Evaluation of Ship Performance in the Actual Sea led by the National Institute of Maritime, Port and Aviation Technology of Japan and National Maritime Research Institute of Japan.

ISO 19030 Standard

The ISO has published ISO19030 (Ships and marine technology -- Measurement of changes in hull and propeller performance) on November 15, 2016. This is the ISO standard to evaluate how much biofouling on hull and propeller affects for the ship performance, composed of the following three Parts:

ISO 19030 (Ships and marine technology -- Measurement of changes in hull and propeller performance)

- Part 1: General principles

- Part 2: Default method

- Part 3: Alternative methods

CMP was deeply involved in the development of this standard from the very beginning. The ISO 19030 Part 2 is the default method with which analyses should be conducted based on sea trial, model ship test or CFD result. Those tests are often conducted on dissociated condition (especially draught condition) with actual operating condition. The ISO 19030 Part 3 is the alternative methods, which has been established representing our opinion. Japanese shipping companies and CMP had been involved to make a proposal, through the industry organization, that there should preferably be alternative methods which would make it possible to evaluate easily and accurately the vessel performance based on the actual operation data.

CMP will conduct the evaluation of the actual hull performance using necessary data provided by each customer, in accordance with the ISO 19030.