28 July 2025

Chugoku Marine Paints’ ISCC Certified Bio-based Epoxy Resin Coating Adopted for Mitsui Chemicals’ Liquefied Ammonia Tanker

Making Vessels Greener with High-Value-Added Coatings

Chugoku Marine Paints, Ltd. (Tokyo: 4617; President & CEO: DATE Kenshi) and Mitsui Chemicals, Inc. (Tokyo: 4183; President & CEO: HASHIMOTO Osamu) are pleased to announce that CMP NOVA 2000 (Bio), a bio-based epoxy resin coating developed by Chugoku Marine Paints that has gained ISCC PLUS*1 certification using the mass balance method*2, has been selected for use on the ballast water tanks*3 of the liquefied ammonia tanker being built by Kegoya Dock Co., Ltd. (Kure, Hiroshima; President: KURUSHIMA Masayoshi).

This coating uses Mitsui Chemicals' bio-based epoxy resin, which has been certified by ISCC PLUS using the mass balance method to reduce CO2 emissions.

A research by Chugoku Marine Paints suggests that this will be the first time in the world that a bio-based epoxy resin coating has been adopted for marine vessels.

In addition, the tanker’s bottom is coated with Chugoku Marine Paints’ fuel-efficient antifouling SEA PREMIER 2000 PLUS, which is expected to reduce CO2 emissions during operation. The adoption of these high-value-added coatings is expected to significantly reduce CO2 emissions during paint production and after the vessel enters service. The vessel is scheduled to be completed in May 2026.

■ Bio-based Epoxy Resin Coating "CMP NOVA 2000 (Bio)"

CMP NOVA 2000 (Bio) is a bio-based epoxy resin coating for ballast water tanks that has been ISCC PLUS-certified and is made from epoxy resins derived from biomass using the mass balance method being rolled out by Mitsui Chemicals. Delivering the same level of paint quality and coating performance as petroleum-derived products, the new coating maintains functionality, while its biomass-derived content offers the ability to reduce CO2 emissions by approximately 660 kilograms per one ton of paint (provisional value) compared to the existing CMP NOVA 2000.

(Image photo) Bio-based epoxy resin

■ Fuel-Efficient Antifouling "SEA PREMIER 2000 PLUS"

As ammonia is attracting attention as a next-generation low-carbon energy (next-generation fuel), the shipbuilder is proactively choosing products with high environmental performance for use in the new vessels. The adoption of SEA PREMIER 2000 PLUS fuel-efficient antifouling is expected to improve fuel efficiency by 5 to 8 percent compared with conventional antifoulings, thereby reducing CO2 emissions during vessel operation.

■ Environmental Performance Improvements through High Value-Added Coatings

| Adoption part | Product name | Environmental Performance |

| Ballast Water Tank |

"CMP NOVA 2000 (Bio)" bio-based epoxy resin coating (ISCC PLUS certified) |

Switching to bio-based coatings using the mass balance method is expected to have an effect of reducing CO2 emissions by approximately 660 kilograms (provisional value) per one ton of paint. |

| Underwatar Hull |

"SEA PREMIER 2000 PLUS" fuel-efficient antifouling |

Its smooth coating film reduces friction resistance of water flow, and the innovative antifouling agent Selektope®, which is highly resistant to barnacles, substantially minimises the increase in horsepower arising from underwater hull fouling. This is expected to reduce fuel consumption by 5 to 8 percent, leading to the reduction of CO2 emissions. |

■ The Liquefied Ammonia Carrier

| Shipowner |

Kinkai Tanker Co., Ltd. (5-25-11 Shiba, Minato-ku, Tokyo) |

| Consignor | Mitsui Chemicals, Inc. (2-2-1 Yaesu, Chuo-ku, Tokyo) |

| Shipbuilder | Kegoya Dock Co., Ltd. (6-1-11 Kegoya, Kure City, Hiroshima Prefecture) |

| Paint Manufacturer | Chugoku Marine Paints, Ltd. (2-6-1 Toranomon, Minato-ku, Tokyo) |

| Type of Vessel | Liquefied Ammonia Tanker |

| Completion Date | May 2026(planned) |

*1:ISCC PLUS certification

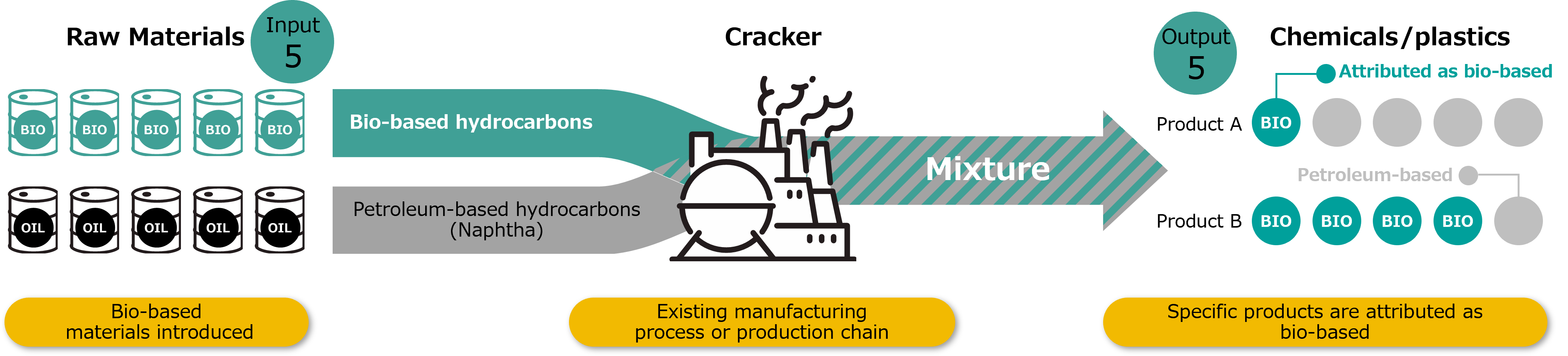

*2:Mass balance method

The Ministry of the Environment’s Roadmap for Bioplastics Introduction defines the mass balance approach as “A method in which, during the process of turning raw materials into final products and the distribution process (chain of custody), raw materials with certain properties (e.g., bio-based raw materials) are mixed with raw materials that do not have the properties (e.g., fossil-based raw materials); thus, the properties are assigned to a portion of the product according to the amount of input of the raw materials with those properties.”

The physical properties of plastics and chemical products made under the mass balance method do not differ from their fossil-derived counterparts. The mass balance method also allows for the use of biomass in the production of materials where it has traditionally been difficult. Therefore, the mass balance method is a significant means of increasing the adoption of biomass in society and realizing a carbon neutral society. As of June 2025, around 40 products across the Mitsui Chemicals Group have already switched to the use of biomass resources based on the mass balance approach. Mass balance also has a crucial role to play in chemical recycling, which is set to be rolled out as a recycling solution that will pave the way for a circular economy.

*3:Ballast water tank

Cargo vessels, such as tankers and bulk carriers, are designed to remain stable when loaded with cargo. However, once the cargo is unloaded, the vessel rises higher above the water surface due to buoyancy, causing instability. To maintain stability, ballast water tanks are used to pump seawater into the vessel as ballast, replacing the cargo.

Contact

Chugoku Marine Paints, Ltd. Global Marketing and Planning Division, Sales Headquarters (TEL: +81-3-6457-9368)

Please click here to contact us via website.

Mitsui Chemicals, Inc. Corporate Communications Department (TEL: +81-3-6880-7500)